Prosthetics

Exploring the complexity of human physiology and engineering limits.

The Prosthetics Team is looking for new members!

Past publications

Abstract

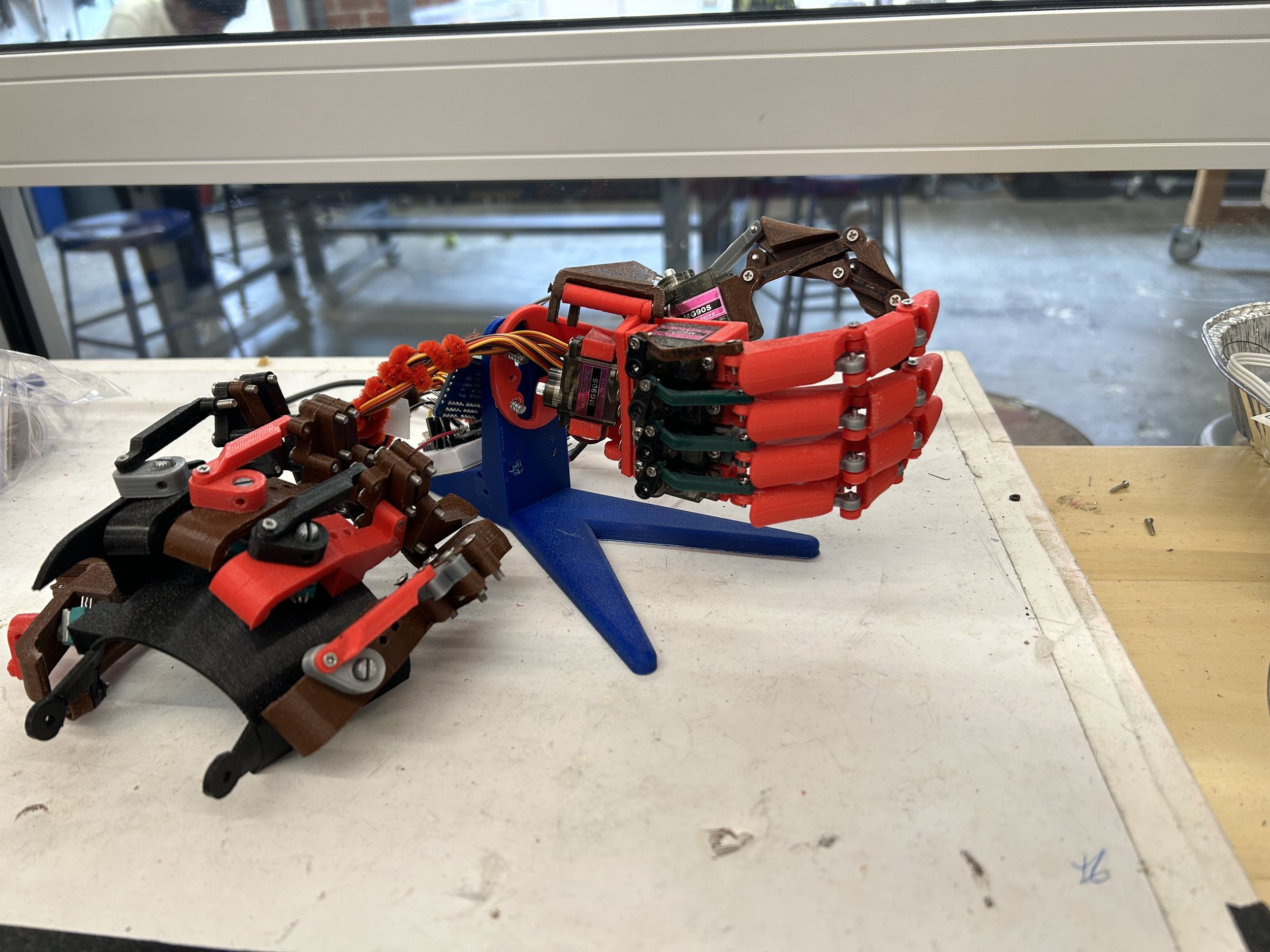

The prosthetics groups’ goal is to expand on the work of E-Nable (a non-profit organization that provides 3D printable hand and arm designs). WISRD is listed as a chapter on the E-Nable website meaning we are certified to print and distribute prosthetics of no cost to those who need them. The prosthetics group hopes to stay involved with E-Nable and build upon their work to create a brainwave-controlled prosthetic hand. We will continue to use our 3-D printers for exciting STEM-based advancements and help people globally who are less fortunate than us. 3-D printing is revolutionizing prosthetics in both function and cost, especially for children and adolescents. A prosthetic arm can cost around 40,000 dollars at the time of this writing depending on technology and amount of function. Parents of a child with upper quadrant irregularities might have to spend the amount previously stated every time their child grows.

Current Participants- could it be you?

Project Alumni

Nnenna B. ‘23 (PI)

Zaniyah H. ‘23

Olivia C

Lea B

Grace K

Emily R

Plan

Stage 1

Arduino

Python

Review Cole’s journal on smile motor

Research

Brainwave controlled prostheses

How brainwaves control movement of limbs

Articulated hands

Sensory feedback

Stage 2

Look at prostheses designs

Review Emotiv groups’ work

Learn to use an EEG headset

Research

Servo motors

Stage 3

Create glove with sensors

Pick a predesigned prosthesis template

Final Stage

Print and put the pieces together

Testing

Adjustments

Updates- see individual journal pages and posters for work after 2019

2019 Updates

August: E-NABLE is up and running again! The forum was updated, and is now working smoothly! We reached out to a man in Texas, and he wants our help creating an elbow-driven arm. We are talking about measurements and details with him right now, and cannot wait to move forward!

January: E-NABLE has been working on printing and assembling a hand for an amputee who reached out to us. He sent us pictures of his arms so we could take measurements. We then put these measurements into a customizer that customized the files to fit their measurements. We then printed the pieces all separately and then molded certain pieces, as they were too big to print directly on the printer. We molded these pieces by placing them in boiling water and then shaping them by placing them on another piece. We then assembled the pieces together. Finally, we strung the pieces together and we now have an elbow-driven arm! Our final step is to ship it off to the person we made it for.

2018 Updates

August: Over the summer, we have been communicating with many people who would like to be involved in E-Nable. As we are our own chapter now, we can add members to our chapter to collaborate on various projects. We are currently in the process of adding both some assemblers and some designers to our team. As our chapter grows, the more people we can reach to help the community!

April: First day back from break we came back to a broken MakerBot. We are taking it apart and trying to figure the problem out. The printer just stops extruding after a while. The MakerBot just needed to be cleaned. But now the Lulzbot Taz is broken. The screen on the printer says the heater isn’t responding. We figured out that the thermistor is disconnected. We tried to see if we could connect it again. A new thermistor was needed, and since the thermistor is attached to the extruder, we got a new extruder too. The items were replaced and reassembled. We reprinted anemometer parts for the Aerodynamics Lab. We had our poster presentation and talked to Dean Ho about our project. He was very interested in our publicity and asked if we would like to write an article about E-NABLE which would help us gain even more publicity. We will continue communicating with him about this.

March: We printed with a new software, using the Kinect software from Xbox, through a program called Skanect. The program scanned my face and made it into a 3d print file. We then printed it! Something to keep in mind if this is done again is to make sure that your hair is out of your face, as it can interfere with the scan, and to move slowly, but not too slowly. We attempted to print in bronze on the Lulzbot Taz. There was some wood filament stuck in the nozzle that caused half of the print to be in wood, so we cleared it out*. We changed the heat settings to 210° on the extruder and 60° on the platform. We polished the bronze print.*note: if you change the filament, run a random print first with the new filament in so extrude any filament left over from earlier. A print with steelFill failed because the filament is super brittle and snaps throughout the print because the extruder moves. We are trying to figure out a way to keep it from snapping.

February: We got the Credly badge!! We filled out the google docs form to become a real chapter! It says it will take about 1-2 weeks and then we will be on the chapter map.

January: As we start 2018, we have made some goals. The first one is to get approved in January, so we can start the year off making hands. The second one is to make at least 3 different types of hands in 2018. And our third one is to focus on the hands this year and try to keep the 3D printers up to date and maintained so we don’t end up having to focus on fixing them. We looked at the Credly badge we plan on claiming, and it wants evidence attached in order for us to claim it. We posted a video we made of the hand and attached it to the forum. The video can be found on YouTube, It’s titled E-Nable Wildwood Introduction.

2017 Updates

December: A new narrative and reflection process has been presented in the institute, and there has been much success under these new standards. After writing reflections, we have continued to work on the long application process. We’ve filled out all the forms we can, created a youtube and our introduction video, been very active on twitter, joined the e-NABLE Google+ community under our new email, and completed a form of request for becoming a chapter. We have also been in direct contact with members of e-NABLE, and they are following us on our Facebook page. Since our video is up, it is now pending approval again! On our last class of 2017 we leave e-Nable with a plan for next year. The only space we have left to fill out on our form is our credly badge, which is a badge that gives us approval for becoming a chapter. We will continue this in 2018.

November: We are sending our prosthetic to e-NABLE to get verified so we can start our own printing center

September: After reprinting the hand, we decided to stretch the holes using a screwdriver. We connected the forearm to the palm successfully, and are now working on attaching the flexsors to the forearm.The piece that we are working on should end up holding a screw based on the original plans. However, the screws are cracking our pieces, and bolts have proven to be very stable and more accountable. We are creating threads so that we can twist the bolt into place without any cracks. The screws that connect the string from the palm to the forearm were put in incorrectly. They were put in so that the holes faced each other, instead of facing out. We fixed them by rescrewing the bolts. Now something is wrong with the finger joints. When we bend the fingers down, they don’t snap back up. We thought the problem is that the elastic is too loose or that the finger pins are too tight. We figured out that the reason it did this was that one part of the finger was too thick and created friction between the other part.The ring finger is still incorrect while the rest snap back into place. Now we are fixing a printer that’s clogged.

August: The E-Nable team is back and working again!! We have a new member working with us, Emily R. We plan on sending in our test hand and getting approved so we can make a chapter as soon as possible. The wrist portion of the hand finished printing. Next it will be attatched to the palm and the flexsors will be threaded through the wrist, and then it will be complete! We were assembling the hand and the holes in the side of the hand were too small for the pins, so when placing the pins in the hole, the forearm snapped and we are currently reprinting it.

May: All is printed! We are assembling the second and final test hand. We have all of the fingers put together and have the thumb attached to the palm.

April: The hand is so close to being done!!! The printer is also fixed!!! All printers are back up and running! The only thing left to do is figure out how to tie the strings in a way that will make the hand sturdy but adjustable. The Makerbot printer that we have been working on for a while has been completely fixed! We had to completely take the printer apart, replace the wires, and then reassemble everything. It has successfully test printed a bracelet. We also have 95% printed the hand!

March: The Lulzbot Taz is clogged. There weren’t any instructions on how to fix it so first we took apart the nozzle. We needed to take apart the entire printer in order to loosen the grip on the clogged filament. The motor won’t click back into place, might need to contact support. We have finally printed the finger joints! Now, all we have to do is assemble the strings. We have now used 3 3D printers for this hand: Makerbot for the fingers and forearm, Ultimaker for the palm, and Lulzbot for the finger joints.

February: We got replacement pieces for the 3D printer. We fixed one of the printers. Now it is up to date and connected to the computer. It is being used for printing of the palm for the hand. Fixed 3D printed hand by raising palm several mm’s and changing extruder #2 from PVA to ABS. This caused the first layer to be printed as dissolvable filament and the filament stuck to the platform. with the other setting, the dissolvable was printed on top of the ABS filament and it did not stick to it at all.

January: We are coming back from winter break we have made great progress. The hand is 80% done. The only thing left to do is assemble the thumb. We also learned that the strings running from the tip of the fingers to the wrist are supposed to be tied back to the space between the palm and the wrist. We found a letter written by a former student concerning E-Nable. One of the hands printed last year was submitted but sent back because of a problem. The problem had something to do with the wrist. We are not completely sure what the problem was, but we are working on figuring it out. We will then have to do some paperwork and send it back in. We have contacted the former student and asked how to get the paperwork and what was wrong with the hand. We have not gotten a response yet. A few unfortunate things happened today… We ran out of PVA but more is on the way. The palm of our blue K1 hand also broke. As we were trying to reprint the palm, a wire in the wire encasement fried. We remodeled the lab! The 3d printers are now placed more practically, easier to get to.

2016 Updates

December: The right fan in the Makerbot Replicator 2x was replaced. It is functioning well so far. We have assembled certain pieces of the hand, but not all. While I was assembling the thumb, it broke so it is currently re-printing. Once the thumb is done we can finish assembling the hand.

Unload the sides you plan on replacing the fan in.

Turn off the Printer.

Take a 2.5mm hex wrench and remove the two front bolts as well as the fan shield, the fan, two plastic spacers, and the heat sink. Put all of the things you removed aside. Let the fan just hang.

Remove the stepped motor by unplugging it and then slide it our of place. Safely set the motor aside for later.

Using a pair of scissors or wire cutters, cut the zip tie securing the wire encasement to the extruder assembly.

Peel oped the encasement and locate the wire connected to the fan.

Unplug this by holding one side of the plug firmly with one hand and use pliers to unplug. Unplugging may take a while and a few tries, as the plug sits quite firmly.

Reinsert the new fan the same way you removed the old one. It should slide right it.

Organize the wires back into the encasement and close it using a small zip tie.

Reinstall the motor by sliding it back into place and plugging it back in.

Put the heat sink and the new fan back the way they were, and then attach the front bolts with the two plastic spacers, and the fan shield.

Screw the bolts back into place just a little more than hand tight.

November: We are printing the joints for the hand. We are also preparing our poster and researching about flexible filament. We are thinking about using flexible filament, it is strong and durable yet stretches easily and is very flexible. We realized something weird with our prints. The palm and forearm get rough where the dissolvable filament was surrounding it. We used a Makerbot for the print. WE printed a dissolvable filament box around the base of the print in attempt to ensure that the print didn’t have rough parts but that is exactly what happened. Unfortunately we did not document the print settings as we did not think we would have a printing problem. We are looking into what went wrong and then we will try to reprint. We wanted to give the prints an acetone bath to make them shiny and smooth but everytime we tried the prints would break.

After a few attempts, we finally figure out how to do an acetone bath. Here are the steps to completing a successful acetone bath:

Materials needed: your 3d print, acetone, a cloth, a small stove, beaker, string, something to attach the string to.

Set up the small stove in a hood.

Heat it to 100 C.

Place the beaker onto the stove.

Pour 1/4 a cup of acetone into the beaker.

Place your cloth over the beaker to keep in the heat.

Wait about 10 minutes for the acetone to start to boil. (you should be able to see small bubbles once its boiling.

While waiting, place the thing you plan on hanging your 3d print from, above the stove.

String or wrap your string around your print.

Once you have waited 10 minutes, tie the string that your 3d print is attached to onto the thing you plan on hanging it from. Allow your print to hang down fully into the beaker, without it touching the acetone.

Put the cloth over the beaker with your print in it, and close the hood.

Wait 5-10 minutes, depending how big your print is, and then CAREFULLY remove the print, using your cloth, from the beaker and place it on a paper towel.

Wrap or string the string around or through the opposite side of the print than where it originally was attached. (You do this to avoid unevenness)

Repeat steps 9 and 10. (If you feel like less or more time is needed, then do what is necessary.)

Wait 10 minutes for it to dry a little, but make sure to carefully flip it every few minute so it doesn’t stick to the towel, since the plastic is melted. (when flipping be careful not to get fingerprints on the print)

After 10 minutes, allow it to fully dry over night.

Cautions: DO NOT GET IN YOUR EYES OR MOUTH, wear goggles, try not to touch the acetone at all, make sure the string is strong enough to hold your print in the beaker, don’t let it be in the acetone vapor for too long because your print will melt.

October: The Makerbot was having a lot of issues so we decided to use the Ultimaker instead.We made a Facebook page for E-Nable. We are also making a donation page, and we are working on making a Trello Page.

September: we created a Facebook page about our school’s E-Nable chapter and have been emailing with the E-nable community. We have also been working on a test hand. We started printing the palm. The first time we printed the palm, it didn’t work out because certain parts of it were so delicate that we accidentally broke them off. Then, we accidentally printed it in the wrong material (dissolvable filament). Eventually, we printed it right and printed the forearm as well.

Solutions

Replacing the Makerbot Replicator Fan

How to replace Makerbot Replicator:

Unload the sides you plan on replacing the fan in.

Turn off the Printer.

Take a 2.5mm hex wrench and remove the two front bolts as well as the fan shield, the fan, two plastic spacers, and the heat sink. Put all of the things you removed aside. Let the fan just hang.

Remove the stepped motor by unplugging it and then slide it our of place. Safely set the motor aside for later.

Using a pair of scissors or wire cutters, cut the zip tie securing the wire encasement to the extruder assembly.

Peel oped the encasement and locate the wire connected to the fan.

Unplug this by holding one side of the plug firmly with one hand and use pliers to unplug. Unplugging may take a while and a few tries, as the plug sits quite firmly.

Reinsert the new fan the same way you removed the old one. It should slide right it.

Organize the wires back into the encasement and close it using a small zip tie.

Reinstall the motor by sliding it back into place and plugging it back in.

Put the heat sink and the new fan back the way they were, and then attach the front bolts with the two plastic spacers, and the fan shield.

Screw the bolts back into place just a little more than hand tight.

Replacing the Makerbot Replicator Fan

How to replace Makerbot Replicator:

Unload the sides you plan on replacing the fan in.

Turn off the Printer.

Take a 2.5mm hex wrench and remove the two front bolts as well as the fan shield, the fan, two plastic spacers, and the heat sink. Put all of the things you removed aside. Let the fan just hang.

Remove the stepped motor by unplugging it and then slide it our of place. Safely set the motor aside for later.

Using a pair of scissors or wire cutters, cut the zip tie securing the wire encasement to the extruder assembly.

Peel oped the encasement and locate the wire connected to the fan.

Unplug this by holding one side of the plug firmly with one hand and use pliers to unplug. Unplugging may take a while and a few tries, as the plug sits quite firmly.

Reinsert the new fan the same way you removed the old one. It should slide right it.

Organize the wires back into the encasement and close it using a small zip tie.

Reinstall the motor by sliding it back into place and plugging it back in.

Put the heat sink and the new fan back the way they were, and then attach the front bolts with the two plastic spacers, and the fan shield.

Screw the bolts back into place just a little more than hand tight.